Most read

- 1. Danobatgroup sets a new turnover record of €344 M in 2024

- 2. Danobat revolutionizes manufacturing with a new precision robot

- 3. MONDRAGON expands its digital presence with Bluesky

- 4. MONDRAGON leads ASETT, the Social Economy Hub for social transformation

- 5. Orbik Cybersecurity, the first technological start-up to become a co-operative

- 6. Eika acquires Stone Cooker S.L and its innovative 'Suiseki' table to boost growth

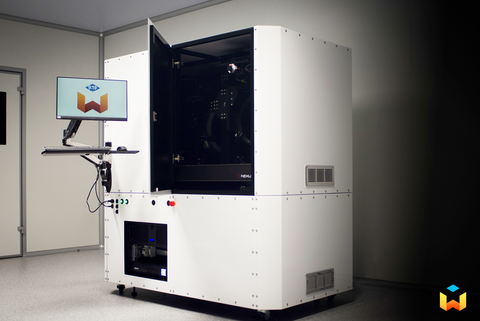

Fagor Automation has developed QUERCUS, the CNC automation system

The industrial manufacturing sector is constantly evolving and has been calling for technologically advanced, flexible and customized solutions to increase productivity, without any loss of precision, while ensuring the highest quality results.

In response, Fagor Automation has developed QUERCUS, the CNC automation system. QUERCUS is an integral solution that includes, apart from its numerical control, servo modules, power supplies, communication buses, spindle motors, and full digital feedback systems.

These innovations will be revealed at the upcoming EMO machine tool trade show, at Hannover, Germany, demonstrating its ability to meet the highest precision requirements and increase efficiency of manufacturing processes.

This is not only a solution for high-performance machines such as milling machines, lathes, and laser cutters; but also for the latest generation of equipment used in additive manufacturing and production systems for the 3C industry (computer, communication and consumer electronics).

“QUERCUS constitutes the renovation and rejuvenation of our CNC automation system built upon a numerical control, with improved control algorithms, and more compact hardware. Particular attention was paid to the drives and power supplies that have a completely overhauled control and power circuit design, while incorporating next-generation electronic components to increase overall efficiency”, explained the Worldwide Sales Manager of Fagor Automation CNC business, Asier Lopez.

This solution keeps certain features in mind, such as the ease of integrating third-party applications, flexibility, and customization.

These developments offer important advantages to machine tool manufacturers such as simple assembly and a very significant reduction in space required for the various modules. End users, on the other hand, reap certain benefits with the inclusion of a totally new HMI, which comes with updated screens that are even more intuitive and easier to use.

“Our solution brings together all of the market’s requirements and, at the same time, can respond to the constantly evolving challenges of the future, given that machine tool manufacturers and users will need to keep themselves at this technological forefront. This is a system offering our users the possibility to evolve and become more competitive,” added the CNC Product Manager of Fagor Automation, Eva Gayubo.

Utilizing the latest technology, the QUERCUS system contains completely reengineered hardware and new circuits, saving space inside the electrical cabinet and reducing the overall size and final cost of the machines.