Most read

- 1. Barcelona Circular, new project that strengthens MONDRAGON's roots in Catalonia

- 2. Danobatgroup sets a new turnover record of €344 M in 2024

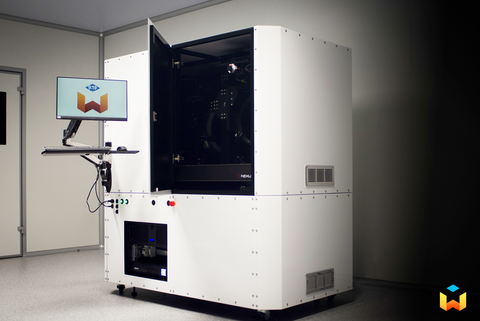

- 3. Danobat revolutionizes manufacturing with a new precision robot

- 4. MONDRAGON expands its digital presence with Bluesky

- 5. MONDRAGON leads ASETT, the Social Economy Hub for social transformation

- 6. Orbik Cybersecurity, the first technological start-up to become a co-operative

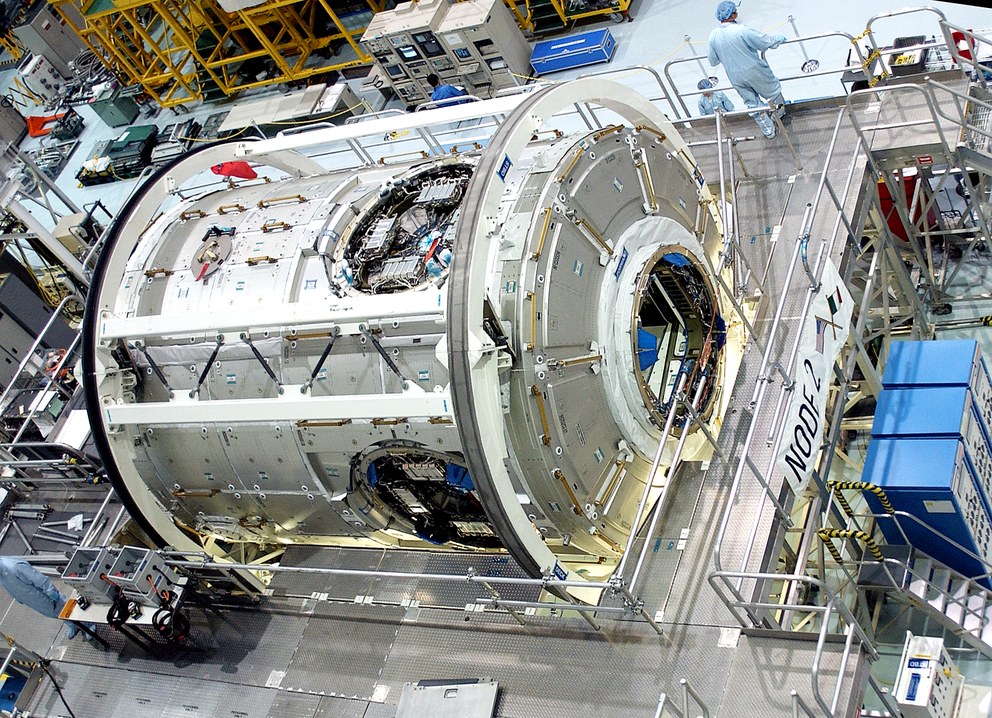

Fagor Automation continues to successfully penetrate Aerospace industry

Over the past several years Fagor Automation’s Research & Development team has developed many specific features for the aerospace industry with CNC 8055 & CNC 8065 platforms. They were dedicated to ensuring the CNC platforms contained the capability to provide the high performance features the Aerospace manufacturers required. On high order of these features was a combination of attaining a higher level of speed and precision-especially for machining composites.

The Fagor Automation R&D team tasked themselves with developing many features including an on-board High Speed Surface Accuracy system (HSSA) combined with various algorithms and specific features like: tilt plane vector compensation, dual ultra precision resolution & accuracy, all delivered through complete ensemble of Fagor products. The monumental task has been successful based upon the results shown thus far.

As of 2014, Fagor Automation has successfully installed CNC 8055 or CNC 8065 Systems in the Aerospace Industry Leaders Manufacturing facilities.